A btu is the amount of heat required to raise or lower the temperature of 1 pound of water by.

Determining the amount of concrete needed for a cooling tower.

Tower tech refrained from active involvement in the construction of new field erected concrete cooling towers from.

From 1995 to 2000 tower tech and its offshore partners built modular concrete cooling towers in the united states brazil italy south africa austria france peru india china thailand and other places.

Determining the amount of concrete needed for a cooling tower 10 points ec name.

To complete this extra credit project you must do the following.

Determining cycles of concentration.

The second method is to calculate an estimate based on the dimensions of the system piping and sump.

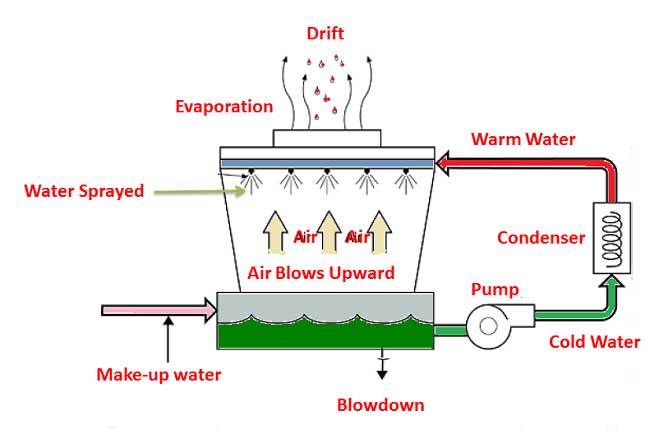

The heat picked up in the heat exchanger is returned to the cooling tower where it is rejected to the atmosphere by evaporative and convective cooling.

W 0 3 to 1 0 percent of c for a natural draft cooling tower w 0 1 to 0 3 percent of c for an induced draft cooling tower w about 0 01 percent or less of c if the cooling tower has windage drift eliminators concentration cycles in petroleum refinery cooling towers usually range from 3 to 7.

A cooling tower ton is defined as.

1 cooling tower ton 1 tonsevap 1 tonscond x 1 25 15000 btu h 3782 k calories h 15826 kj h 4 396 kw the equivalent ton on the cooling tower side actually rejects about 15000 btu h due to the heat equivalent of the energy needed to drive the chiller s compressor.

Ultimately nearly two hundred concrete towers were erected.

1 turn in a written extremely neat solution with an explanation to each problem on a separate sheet of paper 2 the questions must be written prior to the solution 3 present your solution to me.

The purpose of a cooling tower is to conserve water.

Math 230 calculus ii the amount of extra credit depends on the problem s di culty as well as the amount of work required to complete the project.

Also brief about cooling tower mass balance of make up water requirement in system drift losses or windage evaporation losses blowdown or draw off.

The first method is to estimate the volume based on system tonnage typically 3 to 10 gallons per ton depending on the type of tower but accuracy discrepancies may result in chemical underfeed or overfeed.

This shape also maximizes the natural upward draft of hot air without the need for fans.

Not only is the shape stronger than either a cone or a cylinder it takes less material to build.